Contact

igus® Ireland

igus® Ltd.

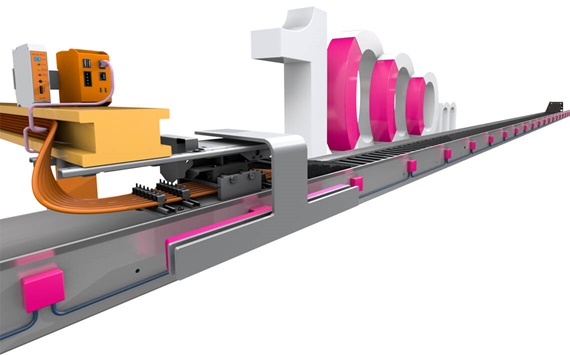

System-dependent imprecision due to static force limits for travels > 150m are a thing of the past.

Now there is the new EC. PR module. Here, force limits are dynamically adjusted with information from PLC control systems, OPC-UA servers, or analogue (4-20 mA) path measurement systems (Profinet /EC. PP). This reduces repair cost and effort; replacing a stacker reclaimer , for example, costs €30,000 or more.