Change Language :

New products in energy chains project planning

News 2025

Extended travel of up to 21m with spring

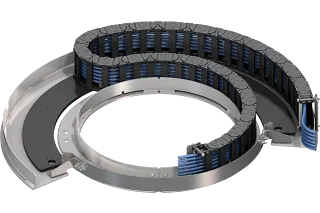

e-spool® theatre HD30

igus® is now expanding the existing product range with travel lengths of 10 and 15 metres to include a further 21-metre variant. This is achieved with the twisterband TBHD30 and can still be operated with the redundant spring system for safe retraction.

- Guide different media and diameters in one system without slip rings

- Motor and control system are no longer required

- The twisterband is successfully used as a slip ring alternative in hundreds of e-spool® applications

- Optimised production process thanks to standardised identical parts

Compact guidance of higher fillings

e-spool® theatre HD42

Thanks to the use of the larger twisterband TBHD42, more cables and larger diameters can be moved over travels of 10 and 15 metres. This increased capacity of the system means that more complex and extensive applications can be realised.

- Guide different media and diameters in one system without slip rings

- Almost the same installation space and approx. 50% more filling compared to the HD30

- Proven spring retraction and larger cable assemblies individually configured and tested

- Material savings: guide more cables safely in one e-spool®, meaning fewer e-spools® are required

40 meter travel length for theatre and stage technology

Design study: e-spool® theatre HD42e

The new standard for up to 40 metres travel, developed in accordance with DIN EN 17206 and DGUV principle 315-390. Equipped with a powerful motor and intelligent control system, the e-spool® HD42e offers higher fill weights and a modular system that enables easy adaptation and expansion.

- Compact size and more flexible travel: With a travel of up to 40m, the e-spool adapts perfectly to your requirements

- Powerful motor and intelligent control system from igus®: The e-spool HD42e is equipped with a robust motor and an intelligent control system that ensure maximum reliability

- Versatility: different media and diameters can be guided in one system without slip rings

- Optimised production process: standardised identical parts ensure an efficient production process

New lightweight design of the guide box

Design study: zig-zag E4.56

Standardised zig-zag guide concept with the e-chain® E4.56 for vertical travels of up to 40m. The tried-and-tested system was designed for use on different shaft end supports and in accordance with DIN EN 17206 and DGUV principle 315-390.

- Lightweight and standardised guide box enables higher payloads

- Modular system with many identical parts

- Similar applications successfully in use since 1999

- Travel can be adapted in 5-metre increments with standardised components

Cost-effective, lightweight and safe rotation of up to 380°

Polymer rotation module ReBeL-Twist

The new polymer rotation module is designed to fit axis 1 of the ReBeL and Universal Robot UR10e and enables simple integration.

- Standardised guide segments: suitable for different chain widths from 20 to 50mm. All media are safely guided during the movement of the robot

- Simple installation: few components and interfaces ensure quick and uncomplicated installation

- Tested in the igus® laboratory

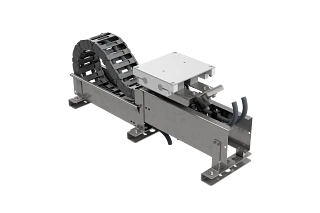

Steel guide trough ST200

Cost-effective, durable and easy to install

The steel guide trough ST200 sets new standards in the guidance of energy chains, especially for the common rol e-chains of the 2828R, 3838R, 4040R and 5050R series. The system was developed for travels of up to 200m and offers you a cost-effective solution without an additional glide bar and with simple installation.

- Ideal for long travels and demanding applications

- No additional glide bar required: simplify your installation and maintenance

- Reliability and durability: developed and tested in the igus® laboratory for the highest quality and reliability

- Material savings by dispensing with the glide bars

With our newsletter you will no longer miss any news from igus. Stay up to date regarding our company and motion plastics. Be the first to discover new products, exciting applications, current laboratory reports and much more.

News 2024

e-spool® theatre 10m and accessories

Developed for theatre and stage use in accordance with DIN EN 17206 and DGUV principle 315-390. Since last year, it has become an indispensable standard in theatre and stage technology. A further, more compact size with a travel of 10 metres and the new, optional accessories (ratchet, brake and tethering brackets for ceiling installation) now round off the product range. The extended length of the chain can be individually positioned using the ratchet. The brake ensures controlled winding. The connection brackets help when installing under the customer structure

.

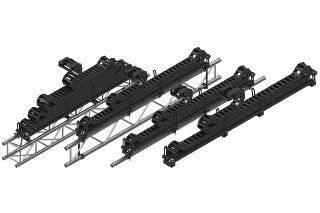

Low-cost zig-zag e-chain®

Lightweight and cost-effective

All the advantages of an e-chain® with an innovative guide concept for travels of up to 10 metres. The system was designed for use on different shaft end supports and in accordance with DIN EN 17206 and DGUV principle 315-390. The current system length is 2.16 metres. Different chain widths are possible, inner widths from 075 to 150mm are available.

- More than 50% weight reduction compared to the standard zig-zag basket and therefore higher payload

- Price reduced by up to 50% compared to the standard zig-zag basket

- Lower drive power due to weight reduction

- Quiet plastic e-chain®

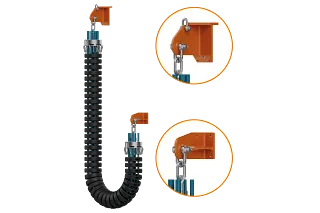

e-spool® microphone and e-spool® microphone stereo

The e-spool microphone fills a gap in the field of sound technology and is particularly versatile thanks to its compact size and lightweight design. The use of the twisterband eliminates the need for a slip ring. This ensures uninterrupted sound transmission over an extension length of 30 metres. With the e-spool microphone stereo, two cables are run in parallel so that two microphones can be connected. Both systems are supplied complete with motor and control system, the e-spool® microphone stereo additionally with microphone rail for two microphones.

e-loop® retrofit mounting console

Together with the new retrofit mounting consoles, the e-loop® is a ready-to-connect energy supply system for land drilling rigs. The standardised consoles for easy connection of the moving end and fixed end of the e-loop® ELP.300 to standard top drive models complete the e-loop® product range.

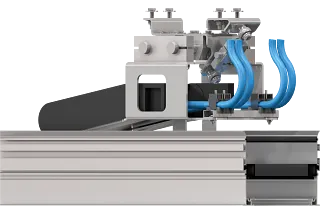

Smart support plates / floating moving end

The new igus® standard for support plates and floating moving ends with identical hole pattern and same attachment height for an even more installation-friendly connection of the e-chain system® to the moving end The system is supplied with an integrated holder for the strain relief and can be equipped with EC.P push/pull force monitoring.

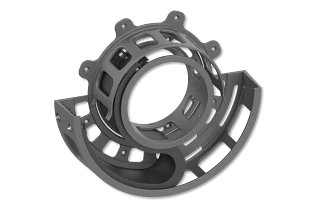

SRM-L steel rotation module light

Simply turn safely

A standardised guide trough for different chain widths including preparation for smart plastics end position control

- Price reduced by up to 40% compared to the SRM

- Design modelled on the proven PRM system

- Fewer components and up to 40% less weight compared to the SRM

- Preparation for end position monitoring

- Durable and low maintenance

- Different media in one system

Dimensions [in mm]

Outer diameter: 600

Inner diameter: 300

System height: 75 to 165

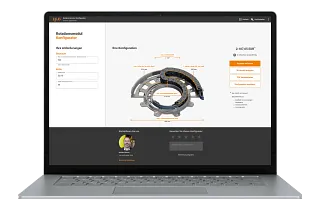

RMC rotation module Online configurator

Occasionally, the numerous standards do not fit into the available installation space and a custom rotating energy supply in a different installation size has to be elaborately designed. Configuring the perfect rotating energy supply system for your application is easy and takes just a few seconds - now possible with the new Rotation Module Configurator. With an outer diameter of 200mm to 2,500mm, you receive a finished standard in your desired size, which you can order directly online.

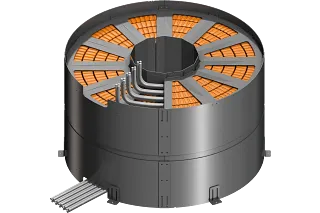

Design study: TRM triflex® rotation module

With five triflex® chains installed, the new TRM offers space for a variety of cables and other media. The compact type (outer diameter 1,300mm, installation height less than 1m) allows for the safe realisation of a 1,800° rotation angle.

News 2023

Theatre e-spool® 10m and 15m

e-spool® energy chain system - For theatres and stages

Discover the energy chain system for theatres and stages based on DIN EN 17206 and DGUV principle 315-390. e-spool® is a cable guide with automatic retraction by spring tension. A new tension-optimised e-chain® is guided on a drum and ensures the correct length and tension of the energy supply system thanks to an integrated retaining spring. The twisterband connects the drum to the shaft block, which serves as an interface to the permanently installed cable.

- Different media and diameters guided in one system

- Price reduced by approx. 50% compared to previous e-spool® solutions

- Developed in accordance with DIN EN 17206 and DGUV principle 315-390

- Optimised production process thanks to standardised identical parts

- Optionally with monitoring of the spring force/rotation sensor monitoring

Dimensions [in mm]

Height: 1,050

Width: 950

Depth: 950

Complete zig-zag system

Up to 15 metres high on trusses

The new standard in theatre and stage technology scores points with its significantly reduced weight on the trusses, modular design and travels of 5-15 metres. The package includes fixings for trusses, the support plate at the moving end and the optional safety package in accordance with DIN EN 17206 and DGUV principle 315-390 to round off the new system.

- 30% weight reduction compared to the previous design

- Price reduced by 20%

- Low-maintenance and expandable system

Dimensions [in mm]

Length: 2,000

Width: 410

Height: 620 to 1,350

Design Study: PRM-V plastic rotation module

For vertical installation

Safe rotating energy supply for vertical installation with additional guide elements, e.g. for lateral acceleration and freely selectable fixed end position:

- PRM-V polymer rotation module up to 500mm outer diameter

- Safe complete solution for vertical use

- All media in one system

- No sliding contact

- Up to 50% cost savings thanks to the new standard - no customised engineering and testing required

- Saves resources by using ready-designed and tested systems

- Material-saving and production-optimised design

Design study: SRM-V steel rotation module

For vertical installation

Safe rotating energy supply for vertical installation with additional guide elements (magsnap/guidelok rockers)

- SRM-VM1000 with magsnap magnets for outer diameters of up to 1m

- SRM-VG2000 with guidelok rockers for outer diameters of up to 2m

- Safe complete solution for vertical use

- All media in one system

- No sliding contact

- Up to 50% cost savings thanks to the new standard - no customised engineering and testing required

- Saves resources thanks to the use of fully designed and tested systems

- Material-saving and production-optimised design

Contact us

Contact details

Seán Ryan086 0329555Submit form

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h