.png?crop=no&color=ffffff00&w=370)

.png?crop=no&color=ffffff00&w=370)

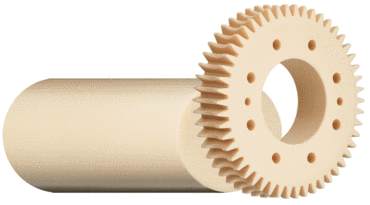

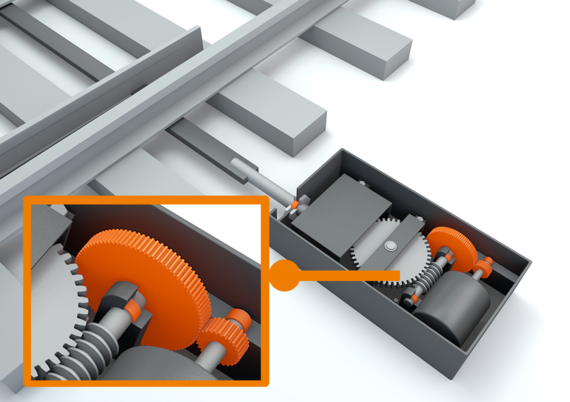

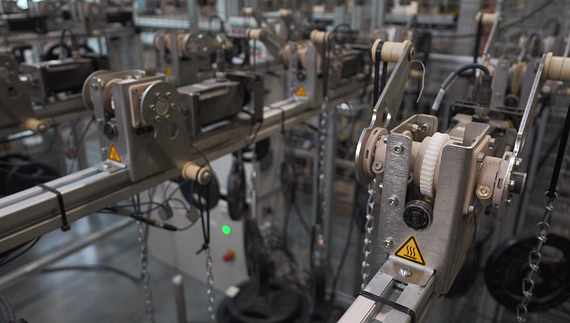

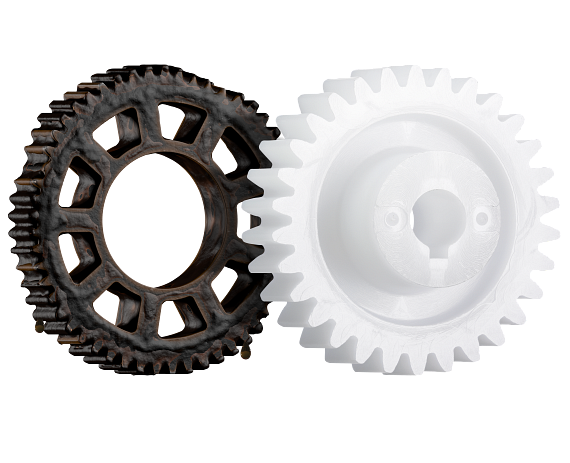

A pinion gear is a round component that has uniformly distributed teeth around its circumference. It transfers force between two rotating gears or between a gear and a rack. Depending on the application, further types are used.

The most common kinds of pinion gears are:

• Spur gears (you can find them in our online shop)

• Racks

• Worm gears

• Bevel gears

Different kinds of gear and toothing are often combined with each other in order to implement certain sequences of movement.

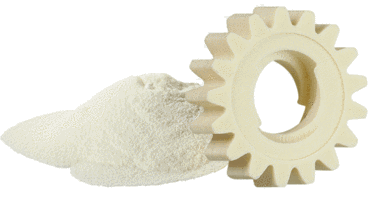

At igus®, gears are made with the help of three manufacturing methods:

• Injection moulding with iglidur® granulate materials

• Mechanical processing with iglidur® bar stock as the material

• 3D printing with iglidur® SLS or FDM materials

Depending on the enquiry, we will advise you on manufacturing methods and work with you to find the best economical solution – free of charge, no strings attached.

Monday to Friday from 8am - 8pm.

24h