On the one hand, the highest priority for machines in food production is their robustness; on the other, they must be easy to clean. To ensure that germs have no chance at all, very strong cleaning agents and lots of water are usually used. They must not have any influence on machine availability in the long term. In this aggressive environment lubrication-free polymer plain bearings prove themselves, which reliably and permanently withstand all adversities.

"We are almost exclusively active in special purpose machine construction," says Simone Singer from the sales and marketing department of the company Singer & Sohn GmbH in Berching, Upper Palatinate. "And the proximity to the Bratwurst metropolis of Nuremberg means that our machines are frequently used in sausage and meat production. We see ourselves as problem solvers for our customers, who generally want to automate work processes with tailor-made systems in order, among other things, to be able to continuously comply with the strict hygiene guidelines. “

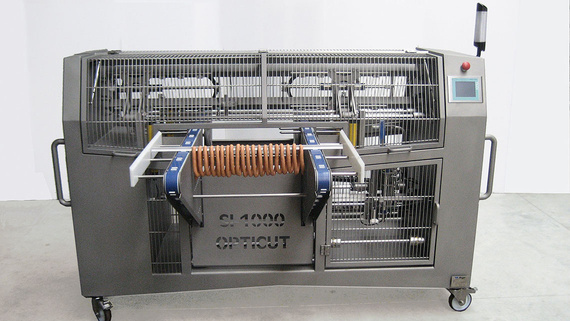

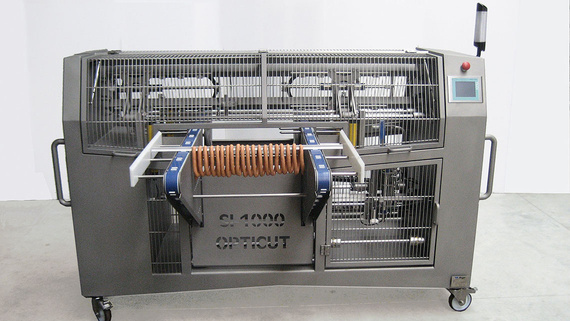

In the sausage chain cutting machine, robust drylin linear guides and trapezoidal lead screws as well as corrosion-free igubal fixed flange bearings also prove their versatility. All supplied parts are designed for direct contact with food. In addition, durable polymer energy supply systems provide the necessary power supply.

"We used to install needle roller bearings," the head of design looks back. "They proved unsuccessful in the harsh operating and cleaning environment. They are very sensitive in that the bearings had to be replaced as soon as a few drops of water penetrated through the seal during cleaning. This was too costly in the long run. In contrast, we are very satisfied with the current solution right from the start. The plastic machine elements, on the contrary, are characterised by a low level of water absorption and are resistant to chemicals. “

The development of the sausage cutting machine 'OptiCUT SI-1000' was based on the specialist's wide experience in the construction of customer-specific models. In the area of the spreading mechanism, a drylin® W single rail guide made of stainless steel with sliding elements made of iglidur® J is used in the sausage chain cutting machine.

Besides extremely insensitive linear guides with JUM liners, plain bearings made of the material iglidur® P210 are also used in the knife edge deflections. They serve as anti-rotation feature and thus ensure high availability. Due to thermal stability and total moisture absorption, the P materials are among the most dimensionally stable under varying environmental conditions. They are recommended for rotation movements for medium to high loads. "Especially in this area, we tested a number of plastics in our machines over the years before we found the right solution now," Dieter Koller looks back.

"Although our machines prove themselves mainly in the meat industry, our transport systems can also be used in large bakeries, for example. Depending on the place of use, the cleaning procedures differ, as do the external conditions. It can get very hot around the ovens. In addition, the rollers of the conveyor belts travel up to 80 m/min. It has taken some time to find a material for all requirements. “

The plain bearing material P210 is now used so frequently that the investment in an in-house tool paid off. The wall thicknesses have been increased from the standard 1 mm to 3 mm so that the service life and runtimes are even better for the customers. "In this way we can guarantee long runtimes over the long term. “