Change Language :

Durable 3D printed worm gears

Up to 80% more wear-resistant than machined or injection-moulded gears

Worm gears can have an extremely long service life if the correct material to 3D print them in is selected. With the optimised properties of the iglidur® materials, the wear rate is low and can be manufactured quickly!

Polymer gears are ideally suited to dry running without lubricating oil - this allows worm gears printed from iglidur® materials to run without lubrication. The customer therefore sees advantages in lower maintenance costs and downtime when designing in worm gears made of high-quality polymer materials.

Should you replace your metal worm gear to an igus® 3D printed one?

Fast online ordering from the 3D printing service: upload spur gear CAD now and find out about prices

► Upload doesn't work? Click here to start the upload directly in the 3D printing service tool.

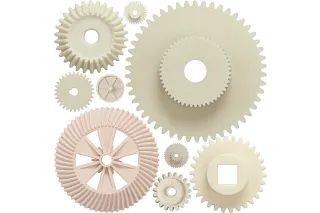

Key advantages of using igus materials in 3D printed gears

► Predictable service life

► Any geometry possible: special shapes and replacement parts

► Optimised tooth root geometry for longer service life

► Self-lubricating: dry operation thanks to solid lubricants

Lasts up to 5 times longer than regular plastic gears

Tested and proven: gears made of iglidur have a considerably longer service life than machined or injection-moulded gears made of regular plastics.

What material is better for what type of gear?

- iglidur I3 is characterised by higher strength, is especially well-suited for spur gears and helical-bevel gears, and can be used for all other kinds of wear-resistant gears.

- iglidur I6 has optimised sliding properties and is therefore ideal for worm gears or other gears where conformity with food standards is required.

- iglidur I8-ESD is suitable for gears where ESD properties are necessary, e.g. for ATEX

Customer applications with 3D printed gears

Frequent asked questions about 3D printed worm gears

A worm wheel is the counter-component to the worm in a worm gear. As sliding capacity is especially important for worm wheels, they are often manufactured from bronze. Printing lower quantities of worm wheels in 3D from high-performance polymer is significantly more cost-effective and, most importantly, faster - whilst delivering comparable properties.

Worm gears are used wherever reliable, precise, quiet gearbox function is necessary. Quiet, robust operation is especially important. Worm gears can be used to implement axle offsets between drive and output. Large outputs can be transferred in very small spaces. Hence, the worm wheel's primary areas of use are conveyor systems, robot technology, profile processing machines, separating systems, extrusion devices, mining machines and rowing machines. Worm gears are also used in presses and rolling mills, stage and theatre equipment, actuators, in machinery construction and lift technology.

A worm gear is a special kind of gear in the shape of a worm. The tooth winds around the gear's shaft, much like that of a screw. The mating gear is the worm wheel. The worm can be thought of as a spur gear with diagonal threads. Its special feature is that the worm only has one tooth. However, there are worms with two or more teeth. This design makes the gear ratio relatively high. A popular property of the worm gear is its self-locking feature. The worm can drive the worm wheel. If the roles are reversed, this is prevented by the self-locking feature. Moving large masses can also be problematic, since abrupt gearbox stoppage is not recommended in such applications.

Not always. Some materials like iglidur® polymers are self-lubricating and designed for dry operation, reducing maintenance.

Where are 3D printed worm gears commonly used?

Important factors include:

- Tooth profile (typically involute)

- Backlash (to prevent jamming)

- Clearance (0.1–0.2 mm recommended)

- Pitch circle diameter (PCD) for proper meshing

Contact us

Contact details

Seán Ryan086 0329555Submit form

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h