Change Language :

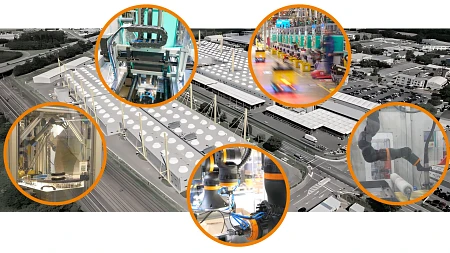

Over 2,500 automation solutions in igus production

No boring jobs: We make short work of routine tasks

Inspiring robot solutions for your production

Discover the future of automation with igus! As the world's leading plastics manufacturer, we focus on intelligent solutions that make your production more efficient and your work more varied. Our vision: Robots take over monotonous, repetitive tasks while you can concentrate fully on the challenging and creative activities. With over2,500 robot solutionsin our own production facilities, we live and breathe automation – and show how innovation and efficiency go hand in hand. Let us inspire you and find out how our robot solutions can revolutionise your processes.

Automated sprue removal: More efficiency in injection moulding

One example of cost-effective automation at igus is the removal of sprues on around 1,000 injection moulding machines. What used to be done manually is now automated by our innovative robot solutions - faster, more precise and more reliable.

A complete solution costs only 10,000 euros and usually pays off after 6 months.

Automated insertion of components into injection moulding machines

Inserting drylin linear carriages into injection-moulding machines used to be a real ordeal for our employees. They had to be inserted hundreds of times a day, followed by a waiting time of 40s per cycle. Today, our low-cost linear robot iSPEL performs this task in record time.

The project costs for this robot solution, including step conveyor, camera and suction gripper, total around22,000 euros. The return on investment is 0.7 years.

Automated thread cutting with cobots

The ReBeL cobot is already being used successfully in numerous places at igus. A prime example is downstream thread cutting: Where monotonous manual labour used to be required, the cobots now handle the workpieces and drill the threads – up to 20,000 times a day.

Programming is easier than ever before thanks to the free igus Robot Control software. You don't need any programming skills! The result? Optimised work safety, increased production speed and fewer rejects. The cost of this automation solution is only 50,000 euros and the payback period is 0.7 years.

Tech up

More consistent results and increased product quality

Cost down

Cost-effective automation solutions with a fast return on investment (ROI)

Proof

Over 2,500 internal solutions in the areas of injection moulding, tapping, assembly and much more.

Sustainability

Reduced consumption of resources and minimisation of waste

More about Low Cost Automation

Contact us

Contact details

Seán Ryan086 0329555Submit form

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h