Change Language :

System E6.1: New generation of quiet-running and cleanroom-compatible e-chain®

Openable along inner and outer radius, from both sides

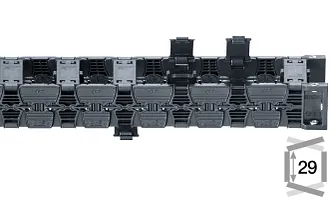

E61.29

inner height hi: 29 mm

inner width Bi: 30 - 140 mm

bend radius R: 55 - 150 mm

pitch: 22 mm

crossbar in the inner and outer radius removable on both sides

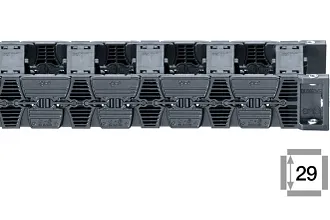

EF61.29

inner height hi: 29 mm

inner width Bi: 30 - 140 mm

bend radius R: 55 - 150 mm

pitch: 22 mm

Crossbars removable along the inner and outer radius

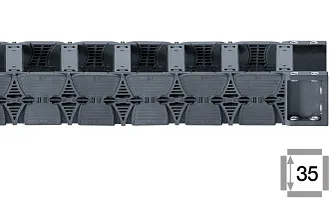

E61.35

inner height hi: 35 mm

inner width Bi: 30 - 140 mm

bend radius R: 55 - 150 mm

pitch: 25 mm

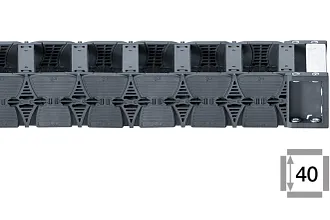

E61.40

inner height hi: 40 mm

inner width Bi: 40 - 300 mm

bend radius R: 63 - 200 mm

pitch: 27.8 mm

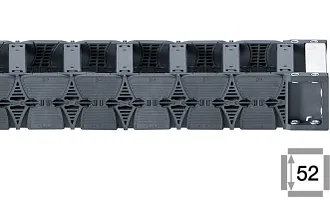

E61.52

inner height hi: 52 mm

inner width Bi: 40 - 300 mm

bend radius R: 75 - 200 mm

pitch: 30 mm

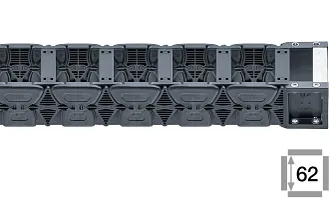

E61.62

inner height hi: 62 mm

inner width Bi: 50 - 400 mm

bend radius R: 115 mm

pitch: 50 mm

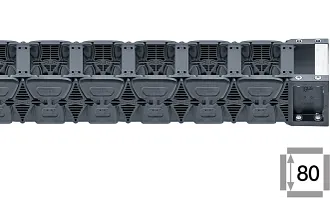

E61.80

inner height hi: 80 mm

inner width Bi: 50 - 600 mm

bend radius R: 150 - 200 mm

pitch: 65 mm

igus® for cleanrooms - suitability of E6.1 e-chain®

By using a special material, the already low abrasion of the e-chain® can be significantly reduced even further. An e-chain® can therefore also be used in many applications where complicated special solutions are required. An extensive test programme has been completed for both sliding and unsupported applications. For many applications, the e-chain® in special materials can be operated practically abrasion-free. Tests by the IPA confirm that the standard e-chain® from igus® fulfil the requirements in cleanrooms and have been "tested and found to be very good". Very high wear resistance of moving parts is required in cleanrooms, so e-chain® , for example, must be highly wear-resistant in order to fulfil the standard requirements for this sensitive environment.

IPA classification - Report IG1303-640-1: ISO Class 1, according to standard DIN EN ISO 14644-1

for series E61.29.050.075.0.CR at v = 0.5 m/s, 1.0 m/s, 2.0 m/s

Extremely low noise

E61.29.070.055.0 at 1m/s = 32dB(A) according to igus® internal test 4479

Contact us

Contact details

Seán Ryan086 0329555Submit form

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h