Change Language :

iglidur® C500 - material data

The most important specifications at a glance

iglidur C500 is a member of the family of extremely media and temperature-resistant iglidur materials X, X6 and A500. Improved wear resistance and greater design freedom - e.g. as a guide ring - characterises this material.

| Descriptive technical specifications | ||

|---|---|---|

| Wear resistance at +23°C | - 🟧 🟧 🟧 🟧 ⬜️ + | More information on wear resistance |

| Wear resistance at +90°C | - 🟧 🟧 🟧 🟧 ⬜️ + | |

| Wear resistance at +150°C | - 🟧 🟧 🟧 🟧 🟧 + | |

| Slide property | - 🟧 🟧 🟧 🟧 🟧 + | Coefficient of friction, dynamic, against steel: µ 0.07 - 0.19 |

| Wear resistance under water | - 🟧 🟧 🟧 🟧 ⬜️ + | |

| Media resistance | - 🟧 🟧 🟧 🟧 🟧 + | More information on media resistance |

| Resistant to edge pressures | - 🟧 🟧 🟧 ⬜️ ⬜️ + | |

| Resistant to shock and impact loads | - 🟧 🟧 🟧 ⬜️ ⬜️ + | |

| Dirt resistance | - 🟧 🟧 🟧 ⬜️ ⬜️ + |

Temperatures

iglidur C500 is one of the most temperature-resistant iglidur materials. As with all thermoplastics, the compressive strength of iglidur C500 decreases with increasing temperatures. The temperatures prevailing in the bearing system also have an influence on the bearing wear. The wear increases with rising temperatures. Additional protection is required at temperatures higher than +130°C.

Temperatures, thermal expansion coefficient

| min. application temperature | Upper application temperature, long-term | Upper application temperature, short-term | In addition secure axially from |

|---|---|---|---|

| -100°C | +250°C | + 300°C | +130°C |

Permissible surface speeds

The maximum permissible surface speed depends on the frictional heat generated at the bearing point. The temperature should only rise to a value that still ensures a sensible spherical insert bearing in terms of wear and dimensional accuracy. The maximum values given in the table only apply to the lowest pressure loads and are often not achieved in practice.

Surface speeds of various iglidur materials

| Maximum surface speeds [m/s] | Rotating | Oscillating | linear |

|---|---|---|---|

| Long-term | 0.9 | 0.7 | 2.4 |

| Short-term | 1.1 | 1.0 | 2.8 |

Permissible pv values

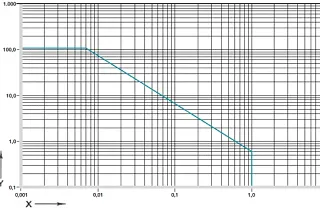

Diagram 01: Permitted pv values for iglidur C500 plain bearings with 1mm wall thickness in dry operation against a steel shaft, at +20°C, installed in a steel housing

X = surface speed [m/s]

Y = pressure [MPa]

pv value, max. (dry)

MPa · m/s

0.70

<a 0="[" 1="o" 2="b" 3="j" 4="e" 5="c" 6="t" 7=" " 8="O" 9="b" 10="j" 11="e" 12="c" 13="t" 14="]" href="/de-de/website/gleitlager/wiki/p-x-v-wert-und-schmierung" uuid="f16b1d8b-0ff1-4a28-951c-3fbeec74eafd" target="_self">Information on pv value and lubrication

Mechanical specifications

The maximum recommended surface pressure is a mechanical material parameter. Conclusions about the tribology cannot be drawn from this. The compressive strength of iglidur C500 plain bearings decreases with increasing temperatures. Diagram 02 illustrates this relationship. Diagram 03 shows how iglidur C500 deforms elastically under radial load. Under the maximum recommended surface pressure of 110MPa, the deformation is about 4.5%.

Friction and wear

The values for friction and wear are even more favourable for iglidur C500 than for the other high-temperature materials iglidur X and A500. The coefficient of friction increases moderately with the surface speed. With the load, the coefficient of friction initially drops significantly to below 0.1 up to 20MPa; with higher loads only slightly. However, friction and wear are also highly dependent on the mating partner. Shafts that are too smooth increase both the coefficient of friction and the wear of the bearing. A ground surface with an average surface finish of Ra = 0.6 to 0.8μm is best suited.

Coefficient of friction against steel (Ra = 1μm, 50HRC):

| iglidur C500 | dry | Greases | Oil | Water |

|---|---|---|---|---|

| Coefficient of friction μ | 0.07-0.19 | 0.09 | 0.04 | 0.04 |

Shaft materials

Diagram 06 shows test results with different shaft materials that were carried out with plain bearings made from iglidur C500. Using the example of a rotational movement with radial loads of 1MPa and a speed of 0.3m/s, it becomes apparent that iglidur C500 is very consistent in wear across a wide range of shaft types. This wear rate spikes in combination with free cutting steel, and, notably so, reduces in combination with HC aluminium. The wear in rotation is higher, especially with increasing radial loads, than with pivoting movements (diagram 07).

Chemical resistance

iglidur C500 plain bearings have very good resistance to chemicals.

The vast majority of organic and inorganic acids do not affect iglidur C500, nor do alkalis or lubricants.

All data at room temperature [+20 °C], + resistant 0 conditionally resistant - non-resistant

| Chemicals | Resistance |

|---|---|

| Alcohols | + |

| Greases, oils without additives | + |

| Hydrocarbons | + |

| Fuels | + |

| Strong alkalines | + |

| Strong acids | + |

| Diluted alkalines | + |

| Diluted acids | + |

Moisture absorption

Installation tolerances

iglidur C500 plain bearings are standard bearings for shafts with h-tolerance (recommended minimum h9). The bearings are designed for press-fit into a housing machined to a H7 tolerance. After being assembled into a nominal size housing, the inner diameter automatically adjusts to the F10 tolerances.

Important tolerances according to ISO 3547-1 after press-fit:

| Diameter d1 [mm] | Housing H7 [mm] | iglidur C500 plain bearing F10 [mm] | Shaft h9 [mm] |

|---|---|---|---|

| up to 3 | +0.000 +0.010 | +0.006 +0.046 | -0.025 +0.000 |

| > 3 up to 6 | +0.000 +0.012 | +0.010 +0.058 | -0.030 +0.000 |

| > 6 up to 10 | +0.000 +0.015 | +0.013 +0.071 | -0.036 +0.000 |

| > 10 up to 18 | +0.000 +0.018 | +0.016 +0.086 | -0.043 +0.000 |

| > 18 up to 30 | +0.000 +0.021 | +0.020 +0.104 | -0.052 +0.000 |

| > 30 up to 50 | +0.000 +0.025 | +0.025 +0.125 | -0.062 +0.000 |

| >50 to 80 | +0.000 +0.030 | +0.030 +0.150 | -0.074 +0.000 |

| >80 to 120 | +0.000 +0.035 | +0.036 +0.176 | -0.087 +0.000 |

| > 120 up to 180 | +0.000 +0.040 | +0.043 +0.203 | +0.000 +0.100 |

Buy iglidur C500 products in the online shop

- Large selection of moulds and materials

- Available within 24 hours

- No minimum order value

- No minimum order quantity

Typical application areas

Contact us

Contact details

Seán Ryan086 0329555Submit form

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h