Change Language :

Smart condition monitoring systems for data, measuring system, and bus cables

Drastically reduce failure costs for heavily used cables ... with i.Sense CF.D

The system components of i.Sense CF.D

Collect data - evaluate data - visualise data

i.Sense EC.P - intelligent line monitoring successfully realised

Other smart solutions for cable monitoring

No additional module is required for condition monitoring (i.Sense) using chainflex® cable. The system can be operated without additional software during integration and networking. In these cases, chainflex® cable takes over 3 possibilities of condition monitoring.

- Tensile and shear force measurement via the cable (CF.P)

- Measurement of the electrical specification of a cable (CF.Q)

- Measurement of the transmission quality (CF.D)

Overview of smart plastic

Insight into the complete product portfolio for Industry 4.0

Table of contents:

- Condition monitoring (i.Sense)

- Condition monitoring products

- Application examples of condition monitoring

- predictive maintenance (i.Cee)

- Application examples for predictive maintenance

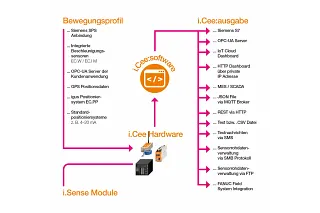

- How does the data flow with predictive maintenance?

How does predictive maintenance work at igus®?

Only the intelligent networking of individual components creates a solid basis for predictive maintenance concepts, also known as predictive maintenance. At igus®, predictive maintenance is summarised under the term i.Cee.

The central element in this area is the i.Cee software. This software, in conjunction with sensors on the energy chain, the plain bearing bush or a linear slide, turns the products available from stock into smart products. This upgrade makes it possible to determine the maximum service life of your igus® product and the i.Cee system also indicates the perfect service time. Algorithms adjust the service life and the service time according to usage. With the software we provide, a few sensors and the new communication module i.Cee:plus II, standard products available from stock can be transformed into smart energy supply or storage technology in no time at all.

i.Sense CF.D - The most important facts at a glance

Contact us

Contact details

Seán Ryan086 0329555Submit form

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h