Change Language :

Predictive Maintenance Solutions for Energy Supply Systems

Eliminate unplanned downtimes and extend service life of igus products

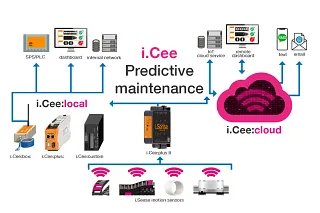

Predictive maintenance solutions start with intelligent networking. At igus®, our i.Cee predictive maintenance software - paired with predictive maintenance sensors on energy chains, bearings, and linear guides, transforms stock products into smart products. This upgrade helps you predict service life and schedule maintenance at the perfect time.

The i.Cee predictive maintenance hardware

You determine the access of data transfers

i.Cee:local

Your data never leaves your corporate network, since the i.Cee software communicates only within the networks you want it to. The options range from an e-chain® within a single machine to a machine park and your own output interface.

i.Cee:cloud

This online solution has two options. In the first, your data is transferred directly to the cloud, where it is made available in a protected area that can be accessed with a browser dashboard. In the second, the data go to an intermediate location on the i. Cee.net: a so-called data concentrator allowing you to stop or adjust data exchange in the cloud.

Applications with smart plastics

Predictive maintenance solutions that utilise e-chain®, chainflex® cables and bearings.

Frequently asked questions regarding predictive maintenance solutions

Predictive maintenance solutions by igus® is powered by the i.Cee system, which uses sensors and software to monitor the condition of components like energy chains and bearings. These sensors detect wear, movement patterns, and other key metrics, allowing the i.Cee software to calculate the optimal service time and maximum service life. This proactive approach helps prevent unexpected failures and costly downtime.

Implementation involves installing i.Cee-compatible sensors on your igus® energy chains and connecting them to the i.Cee software via modules like i.Cee:plus II or i.Cee:box. You can choose between local data processing (i.Cee:local) or cloud-based monitoring (i.Cee:cloud), depending on your infrastructure. The system is modular and can be tailored to your specific setup.

- Preventive maintenance is scheduled at regular intervals, regardless of actual wear or usage.

- Predictive maintenance, on the other hand, uses real-time data to determine when maintenance is truly needed, based on actual component condition. This reduces unnecessary servicing and extends product life.

In manufacturing, predictive maintenance ensures that machines and components like energy chains, bearings, and cables are serviced only, when necessary, based on real-time data. This is especially valuable in high-demand environments like automotive production, where downtime can be extremely costly.

- Avoiding unplanned system downtime

- Reduce maintenance and servicing costs

- Maximise the service life of igus® products

- Improve system efficiency and safety

- Cost savings through reduced downtime and maintenance

- Extended product life

- Improved planning and resource allocation

- Integration with Industry 4.0 and IIoT systems

- Customisable solutions for various industries and applications

- Initial setup and integration with existing systems

- Data management and security (especially with cloud solutions)

- Training staff to interpret and act on predictive insights

- Customisation for complex or legacy systems

Key data includes:

- Movement patterns

- Wear measurements (e.g., clearance in chain links)

- Temperature, vibration, and force metrics

- Usage frequency and load conditions. This data is collected via smart sensors and processed by the i.Cee software to generate actionable insights.

No, wear monitoring systems must be used in conjunction with a new energy chain system. This ensures that the system starts with a clear baseline for wear and performance data, which is essential for accurate predictive maintenance. Retrofitting to older chains may not provide reliable insights due to unknown or inconsistent wear history.

Recommended for you

Contact us

Contact details

Seán Ryan086 0329555Submit form

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h