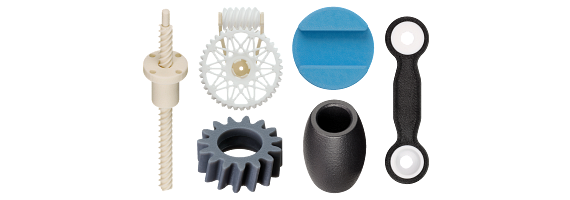

There is a range of traditional plastics that can be used for 3D printing such as PLA, ABS and PVA. At igus®, we have our own range of filaments and laser sintering materials. This allows customers to be able to print custom parts with high wear-resistant materials with good mechanical properties.

igus® uses the EOS Formiga P110. In principle, the tribo-materials iglidur® I3-PL and iglidur® I6-PL should be able to be processed on laser sintering 3D printers with CO2 lasers, if the printing parameters can be adjusted. Due to the different absorption of the laser energy, it is not suitable for low-cost systems such as Sinterit Lisa or Formlabs Fuse 1. The iglidur® I8-ESD-PL is suitable for this due to its black colour.

iglidur® I3 has the longest service life of all igus® 3D printing materials in tests with spur gears. For worm gears, iglidur® I6 is better suited due to the sliding relative movement between the counter partners.

Due to the large number of systems available on the market, no clear recommendation can be made. Basically, the printer should have a sufficiently large and closed installation space as well as a heated print bed. In addition, a print head with two nozzles, or two independent print heads that can heat up to 300°C, is recommended. The device should also be freely configurable, i.e. the processing parameters should be adjustable and it should be possible to process filaments from third-party manufacturers. You should be able to process our filaments on most common printers without any problems.

Monday to Friday from 8am - 8pm.

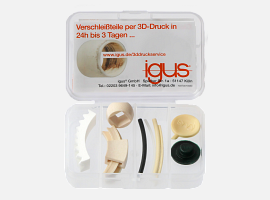

24h