Change Language :

Low profile linear guides- drylin® N

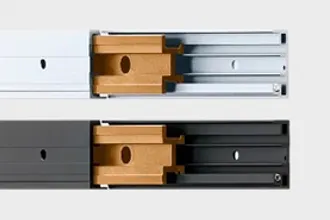

The low-profile linear guide systems are designed for applications where installation space is extremely limited. This compact solution consists of a rail and a guide carriage, with sliding elements made from high-performance polymer for durability and smooth movement. Operating completely without lubrication, the system ensures compliance with the highest hygiene standards, making it ideal for clean environments.

Our drylin® N guides are 100% maintenance-free and lubrication-free, offering long-lasting reliability without additional upkeep. They are corrosion-resistant, hygienic, and resistant to dirt, dust, and humidity, ensuring consistent performance even in challenging conditions. With quiet operation and the ability to join rails for unlimited lengths, these guides provide superior flexibility compared to traditional ball bearing systems.

Low profile linear guide options

Why choose drylin N profile guides?

Can be used in small installation spaces

Thanks to space-saving design with an installation height of 9-12 mm.

Lower energy costs

Thanks to a lightweight, energy-efficient design of the low-profile guide system.

Easy to adjust and position

The defined displacement force makes adjustment and positioning easy.

Quiet operation

Spring pre-load of the carriage and sliding element ensures quiet running.

Less installation time

Thanks to overmoulded carriage (permanent connection between carriage and sliding element).

Easy installation

Thanks to the use of double carriages, it is possible to dispense with several carriages.

More low-profile guide systems

Telescopic rails for temperatures up to 130°C

- Variable stroke lengths up to 600mm

- Use in hygienic environment

- Solid and lightweight

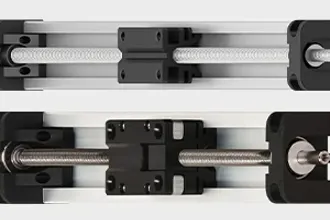

Low-profile guide system with lead screw

- Choice of 3 versions of SLN

- econ basic module / clearance adjustment / pretension

- Configure linear module

General information about low profile guides

Frequently asked questions about low profile linear guides

Low profile guides are low profile linear rails designed to suit small spaces.

You can use drylin® N low profile linear guides in small installation spaces with fairly low loads.

drylin® is lubrication-free, maintenance free, silent running and smooth operational.

Contact us

Contact details

Seán Ryan086 0329555Submit form

Opening hours

Office hours

Monday to Friday from 8 am - 8 pm.

Live chat:

24h