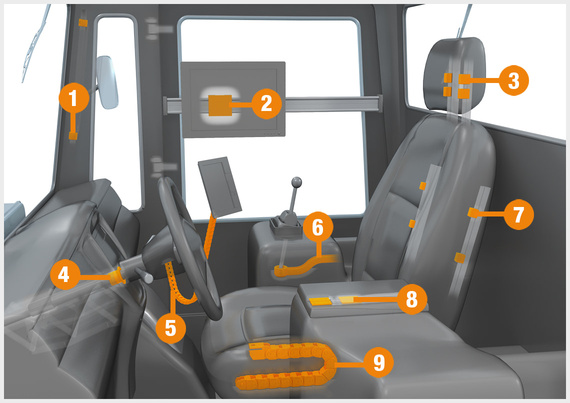

Mirror adjustment: iglidur® J plain bearings

2Monitor adjustment: drylin® W guide carriages

3Seat back adjustment: drylin® W linear guides

4Steering column: iglidur® G plain bearings

5Control elements: triflex® Robotic energy chain

6Hydraulic valve connection: igubal® double joints

7Seat back adjustment: drylin® W linear guides

8Arm rest adjustment: drylin® W linear guides

9Seat adjustment: E2 energy chain and chainflex® cables

igus® has been successfully collaborating with Lemken since 2008. Various Lemken machines are equipped with igus plain bearings, among them the cultivator Karat 9. In the overload elements, the metal bearing points previously used had to be lubricated up to one hour per day to prevent wear and corrosion. By switching to lubrication-free polymer plain bearings, the farmer saves valuable time. Furthermore, the dirt resistance and stability of the plain bearings increase service life and dependability.

Maintenance-free and resistant to dust and dirt, the iglidur® G plain bearings are used in hinges, locking systems and hydraulic cylinders of bale trimming machines from Optimal-Vertrieb Opitz. They replace red brass solutions, that were produced in-house and required both a relatively large installation space and lubricants that polluted the environment. The new polymer bearings need no lubrication and withstand all edge loads without problems.

Monday to Friday from 8am - 8pm.

24h