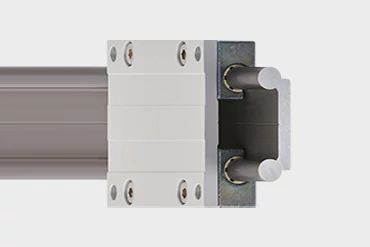

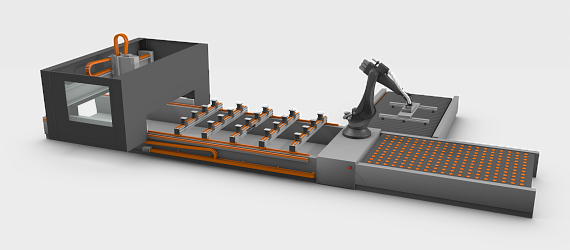

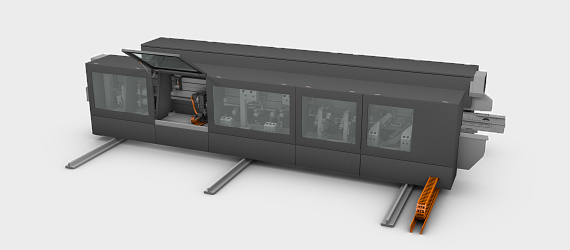

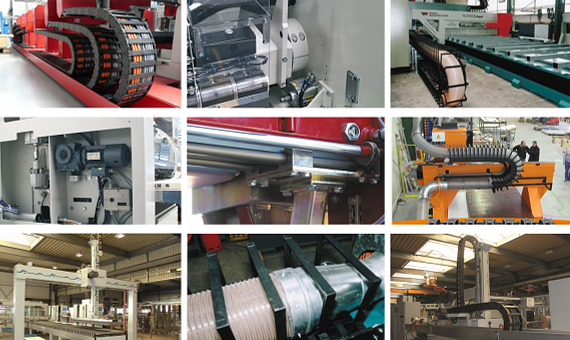

igus ® plastic solutions for moving applications in woodworking machinery help you to reduce installation, handling and throughput times. Time-consuming maintenance work can be minimised with dry running, swarf-resistant solutions from a single source. Where there is dust and swarf, the very tightly sealed igus® energy supplies ensure the safe and secure movement of cables, hydraulic and pneumatic hoses in woodworking machinery or CNC processing centres. In addition, the dry running igus® linear guides, plain bearings and ball bearings are absolutely lubrication- and maintenance-free making them the first choice for woodworking machinery.

Your benefits at a glance:

.jpg?crop=no&color=ffffff00&w=370&quality=80)

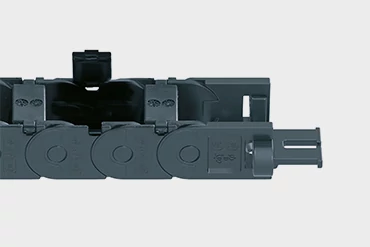

Whether 3D energy supply system, format adjustment with trapezoidal threads or cost-effective PVC cables that function reliably, even when moving.

Find out here how motion plastics solutions demonstrate their technical advantages in many other applications from the woodworking and wood-processing industry

Monday to Friday from 8am - 8pm.

24h