Contact

igus® Ireland

igus® Ltd.

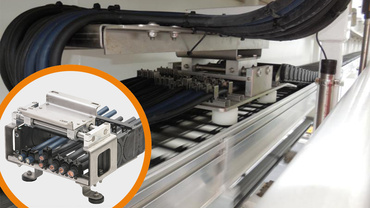

A P4.1 series roller energy chain is in operation at the Port of Rotterdam, one of the largest bulk handling ports in Western Europe. On the ship-to-shore crane, it operates 24/7 continuously over 100 metre travel and without incident. So far it has completed more than 9,000 operating hours.

Triple E-class container ships and the requirements of energy supply for STS cranes

Monday to Friday from 8am - 8pm.

24h